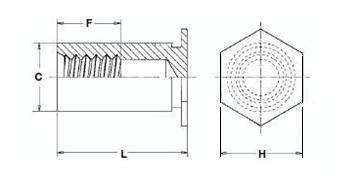

Product size

|

BSO, BSOA, BSOS Blind hole threaded studs  |

Product coding method

|

All dimensions are in millimeters

|

thread*Pitch

|

Steel |

Stainless |

aluminium |

Thread |

Length“L”+0.05-0.13 |

Installation plate thinnest degree |

Installation plate aperture +0.08 |

C -0.13 |

H Nom |

Minimum distance from hole center to plate edge |

|

M3*0.5 |

BSO |

BSOS |

BSOA |

M3 |

6 8 10 12 14 16 18 20 22 25 |

1.02 |

4.22 |

4.2 |

4.8 |

6 |

|

M3*0.5 |

BSO |

BSOS |

BSOA |

3.5M3 |

6 8 10 12 14 16 18 20 22 25 |

1.02 |

5.41 |

5.39 |

6.4 |

6.8 |

|

M3.5*0.6 |

BSO |

BSOS |

BSOA |

M3.5 |

6 8 10 12 14 16 18 20 22 25 |

1.02 |

5.41 |

5.39 |

6.4 |

6.8 |

|

M4*0.7 |

BSO |

BSOS |

BSOA |

M4 |

6 8 10 12 14 16 18 20 22 25 |

1.27 |

7.14 |

7.12 |

7.9 |

8 |

|

M5*0.8 |

BSO |

BSOS |

BSOA |

M5 |

6 8 10 12 14 16 18 20 22 25 |

1.27 |

7.14 |

7.12 |

7.9 |

8 |

|

F Size Min |

Length“L” 6 D=3.2 |

Length“L” 8 10 D=4 |

Length“L” 12 D=5 |

Length“L” 14 16 D=6.5 |

Length“L” 18 20 22 25 D=9.5 |

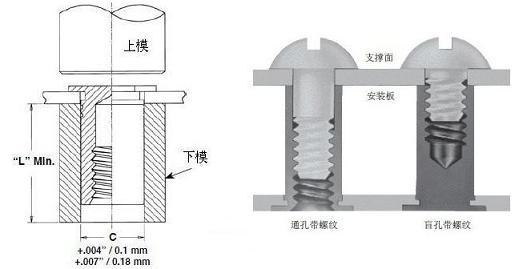

Installation and Use of Products

The self tightening bolt adopts a proven self tightening design, and the product is permanently installed into a pre punched or drilled installation hole thin plate through pressure.

Punch or drill corresponding installation holes on the installation plate. Secondary processing such as deburring is not allowed.

2. As shown in the figure, thread the fastener through the installation hole and place it in the lower mold.

3. When the upper and lower molds are parallel, apply extrusion pressure to rivet the bolts into the plate. After installation, the bolt head plane should be flush with the installation plate surface.

|

|

Thread |

Fastener raw materials

|

Fastener raw materials

|

Fastener raw materials

|

Surface treatment standards |

Surface treatment standards |

Surface treatment standards |

Hardness of installation plate

|

Hardness of installation plate

|

Hardness of installation plate

|

|

series |

Internal,ANSI B1.12B ANSI/ASME B1.13M, 6H |

Heat treated carbon steel

|

7075-T6 aluminium |

300 stainless |

ASTM B633 SC1 (5μm)Type III, Colorless Zinc

|

ASTMA380

|

|

Rockwell hardness not greater than 80

|

Rockwell hardness not greater than 70

|

Rockwell hardness not greater than 70

|

|

BSO |

• |

• |

|

|

• |

|

|

• |

|

|

|

BSOS |

• |

|

|

• |

|

• |

|

|

• |

|

|

BSOA |

• |

|

• |

|

|

|

• |

|

|

• |

Material and surface treatment specifications

Product performance data

When using 5052-H34 aluminum plate with a thickness of. 060 "

|

Thread Code |

Material |

Maximum Record Value

(in.lbs.) |

Installation force (lbs.) |

Pushout force (lbs.) |

Torsion force (in.lbs.) |

pullout (lbs.) |

|

440 |

steels

|

4.75 3.8 2.85 |

1100 |

1600 |

11 |

280 224 168 |

|

6440 |

steels

|

4.75 3.8 2.85 |

1700 |

300 |

11 |

280 224 168 |

|

632 |

steels

|

8.75 7 5.25 |

1700 |

300 |

25 |

310 248 186 |

|

8632 |

steels

|

8.75 7 5.25 |

2400 |

400 |

25 |

310 248 186 |

|

832 |

steels

|

18 14.4 11 |

2400 |

400 |

45 |

580 |

Contact: Mr. Deng

Phone: 13928071304

Tel: 0756-8586520

Email: lizhong@zhjiali.com

Add: 102, Building 4, No. 4 Fuyuan Road, Waisha Village, Shenwan Town, Zhongshan City, Guangdong Province,China